Calculate your potential savings with our ROI Calculator

ROI CalculatorExperience a new era of maintenance excellence with our industry-leading software. From comprehensive asset management to seamless scheduling, empower your team to achieve operational excellence, streamline processes, optimize efficiency, and maximize uptime like never before.

Qualityze Maintenance Management makes preventive maintenance easy, ensuring that your equipment is always ready to perform. Our streamlined approach automates scheduling, tracks equipment conditions, and proactively identifies maintenance needs—helping you avoid breakdowns and maintain consistent productivity levels.

If you have more questions feel free to reachout to us.

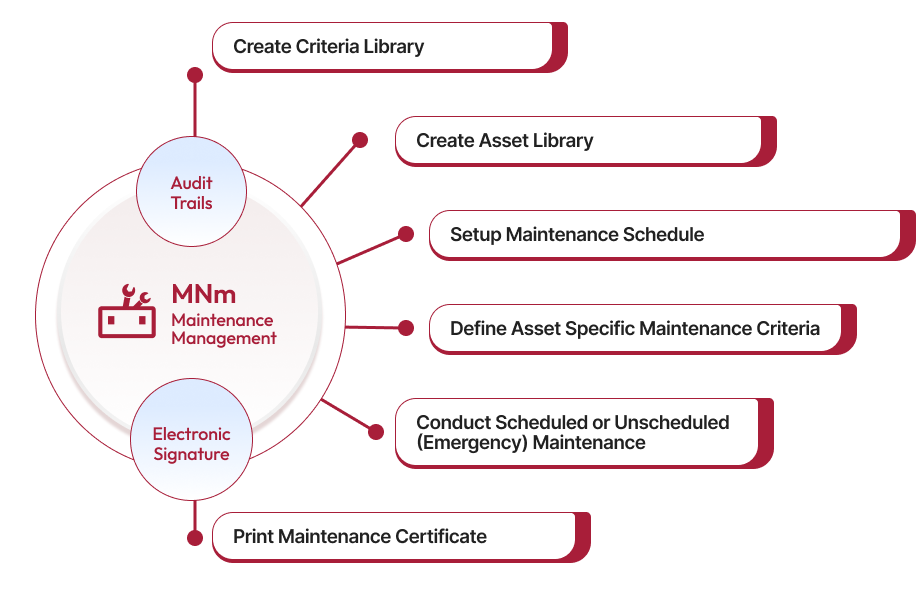

Contact UsQualityze Maintenance Management Software simplifies asset maintenance by automating scheduling, tracking spare parts, and providing real-time visibility into equipment performance. It ensures operational excellence by helping organizations efficiently manage both scheduled and unscheduled maintenance while staying compliant with regulatory standards.

Qualityze Maintenance Management enables businesses to implement proactive maintenance schedules, automate maintenance alerts, conduct timely inspections, and minimize equipment downtime. Regular and prompt maintenance activities help prevent unexpected failures and minimize production disruptions to ensure smoother operations.

Qualityze Maintenance Management Software offers several key features, including: Streamlined Maintenance Scheduling, Comprehensive Maintenance Execution for both scheduled and unscheduled tasks, Automated Maintenance Notifications, Enhanced Equipment Performance Visibility, and Controlled Maintenance Records and Data for compliance and audits.

Yes, Qualityze Maintenance Management can seamlessly integrate with existing business systems like ERP and MES, allowing organizations to synchronize asset-related data across various platforms. It also integrates with Qualityze Nonconformance Management to handle maintenance-related issues efficiently.

Qualityze Maintenance Management adheres to various industry standards, including those set by the U.S. FDA, GMP, GLP, and GCP. It also supports compliance requirements for ISO and FDA 21 CFR Part 11 by providing features like electronic signatures, controlled data management, and maintenance certificates.

With Qualityze, you can easily create a comprehensive Spare Part Library with detailed information such as Spare Part Name, Quantity on Hand, Threshold Quantity, and Status. The system sends automated alerts when inventory falls below the threshold. It helps you avoid shortages and ensure that spare parts are always available when needed.

Defining Asset-Specific Maintenance Criteria helps ensure that all assets are maintained according to their unique requirements. Qualityze allows users to establish standard measurements, tolerance levels, and units for each asset, which helps optimize maintenance activities, prolong equipment lifespan, and reduce maintenance costs.

Qualityze provides enhanced visibility into equipment performance through its robust reporting capabilities. It tracks maintenance activities, records key metrics, and identifies trends, enabling maintenance teams to make informed decisions to improve equipment reliability and optimize maintenance schedules.

Maintenance management ensures the reliability of equipment, preventing unexpected breakdowns, and maintaining production efficiency. Qualityze Maintenance Management helps organizations reduce maintenance costs, extend asset lifespan, and ensure compliance with safety and quality standards, ultimately supporting operational excellence and a safer work environment.