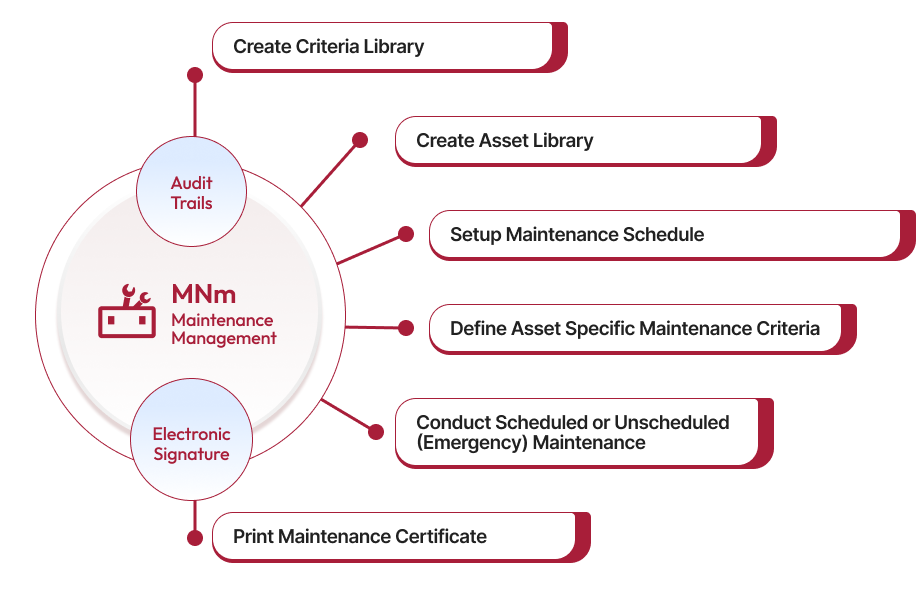

Maintenance Management Software

Master Maintenance Management to Take Control of Your Assets

Experience a new era of maintenance excellence with our industry-leading software. From comprehensive asset management to seamless scheduling, empower your team to achieve operational excellence, streamline processes, optimize efficiency, and maximize uptime like never before.

Proactive Maintenance, Zero Downtime

Qualityze Maintenance Management makes preventive maintenance easy, ensuring that your equipment is always ready to perform. Our streamlined approach automates scheduling, tracks equipment conditions, and proactively identifies maintenance needs—helping you avoid breakdowns and maintain consistent productivity levels.

Efficient Maintenance Scheduling

Seamlessly administer maintenance schedules, guaranteeing timely and proactive maintenance to fine-tune equipment performance and minimize instances of downtime. Qualityze Maintenance Management enables businesses to systematically manage maintenance schedules, guaranteeing timely and proactive maintenance. This approach optimizes equipment performance and minimizes downtime.

Comprehensive Maintenance Execution to Ensure Reliability

Facilitates the execution of both planned and unplanned maintenance tasks effortlessly, promptly addressing crucial issues to ensure the dependability of equipment. Qualityze Maintenance Management simplifies the process of executing both types of maintenance tasks efficiently. This capability contributes to enhanced equipment reliability and prolonged asset lifespans.

Automated Maintenance Notifications

Qualityze Maintenance Management offers an ingenious solution by providing timely automated notifications to equipment owners about imminent maintenance schedules, enabling swift action and diminishing the probability of overlooked maintenance tasks. This feature significantly reduces the risk of missed maintenance, thereby preventing potential downtime and disruptions to operations.

Enhanced Equipment Performance Visibility

Gather enhanced insights into equipment performance by monitoring metrics and recognizing patterns, facilitating well-informed decisions regarding maintenance for optimum operations. With Qualityze you can extract and visualize meaningful insights from maintenance data, such as historical performance trends, and equipment accuracy statistics. This insight-driven approach empowers businesses to maintain equipment at its peak performance, optimizing overall operations.

Controlled Maintenance Records and Data for Compliance

Maintaining accurate maintenance records and data is critical for compliance and audit purposes. Qualityze Maintenance Management ensures and provides the ability to trace maintenance activities. Access to historical data at your fingertips supports audit requirements and contributes to a culture of accountability.

Minimize Risks Through Predictive Maintenance Management

Managing maintenance requirements proactively helps reduce equipment-related risks. Qualityze lets you set unique maintenance standards for important assets and manage activities based on asset history. This proactive approach helps reduce downtime, improve performance, and maintain product quality.

Integrate with Quality Systems for Seamless Maintenance Workflows

Qualityze Maintenance Management integrates with other quality systems to create a complete quality management approach. This integration syncs maintenance schedules, asset information, and compliance records, improving workflow efficiency and data accuracy.

Do you know?

Loading random fact...

saf

COQ

We help you save on cost of quality!

Qualityze Maintenance Management is a comprehensive solution designed to help businesses reduce costs associated with quality issues. By streamlining maintenance processes and ensuring timely inspections, it empowers organizations to minimize downtime, increase productivity, and optimize resource utilization.

Qualityze CAPA Management allows you to save on the Cost of Quality by:

- End-to-End Maintenance Management

Qualityze helps you manage maintenance at every step, from the first schedule to finishing the task and reviewing it. Our system keeps track of all maintenance details so that equipment stays in good condition and works well. With features like automated notifications, emergency maintenance support, and tracking results, we make sure your maintenance process is smooth and effective.

- Configurable to Fit Your Needs

We know that different industries have different maintenance needs. Qualityze lets you customize workflows, criteria, and asset details to fit your business-specific needs. Whether you're in pharmaceuticals, manufacturing, or healthcare, our solution can adjust to your unique maintenance processes.

- Built-In Compliance Tools

Meeting industry-specific standards can be hard. Qualityze Maintenance Management helps you follow standards like ISO and FDA by providing tools to create maintenance certificates, keep audit records, and manage electronic signatures. Our features make it easier to meet all the needed regulations.

- AI-Powered Insights

Qualityze uses AI to make maintenance better. By looking at past maintenance data, our solution can find patterns, predict problems, and give useful advice for taking care of equipment. This helps keep equipment reliable, reduces sudden breakdowns, and saves on maintenance costs.

- Seamless Integration

Qualityze works well with other systems you already use, like ERP and MES systems, to keep data consistent and improve team visibility. This integration ensures maintenance processes match your quality goals and business systems.

- User-Friendly Interface

Our Maintenance Management Solution has an easy-to-use interface that makes the maintenance process simple. Easy navigation, little training, and quick access to important features help your team use the system right away, reducing downtime and improving efficiency.

- Continuous Improvement Culture

Qualityze supports ongoing improvement by giving helpful analytics and tracking maintenance trends. Our system helps teams find ways to make equipment more reliable, reduce problems, and keep high-quality standards over time.

- Unparalleled Support and Training

We are committed to your success. Qualityze offers personal support, complete training, and regular updates to keep your maintenance system working well and meeting your changing needs.

- Global Regulatory Reporting

Following global regulations can be complicated. Qualityze makes it easier by providing ready-made forms, automated workflows, and tracking for bodies like ISO and FDA. Our solution helps you send accurate reports on time, keeping your operations compliant without hassle.

With Qualityze Maintenance Management, businesses can optimize their maintenance operations, mitigate risks, and achieve significant cost savings while enhancing overall product quality and customer satisfaction.

Industry Recognitions

Qualityze Delivering Value Across Key Roles

Discover how Qualityze Maintenance Management helps every key role work better together to ensure equipment reliability, minimize downtime, and optimize operational efficiency—from Quality Assurance Managers to Operations Managers.

For Maintenance Supervisors

Managing maintenance schedules and making sure tasks are done on time is important for keeping assets working well. Qualityze Maintenance Management helps Maintenance Supervisors simplify scheduling, assign tasks, and track progress in real time. This way, they can keep assets in good shape and reduce unexpected problems.

For Production Managers

Production efficiency relies completely on equipment uptime. Qualityze Maintenance Management helps Production Managers minimize downtime by ensuring equipment is maintained as scheduled. This keeps production lines running smoothly, reduces disruptions, and ensures productivity is not compromised.

For Operations Managers

Keeping operations efficient requires reliable maintenance and good decision-making. Qualityze Maintenance Management gives Operations Managers real-time updates on maintenance activities, helping them assign resources and complete maintenance effectively. With Qualityze’s visibility and data, Operations Managers can address maintenance needs early, reduce the risk of disruptions, and keep operations running smoothly.

For Compliance Officers

Following industry regulations requires keeping detailed records and proper documentation. Qualityze Maintenance Management helps Compliance Officers track maintenance tasks, generate maintenance certificates, and keep audit trails to ensure compliance with standards like ISO and FDA. The platform's advanced features make sure all regulatory needs are met, lowering compliance risks and making audit preparations easier.

For Risk Management Professionals

Identifying and reducing risks is key to good maintenance management. Qualityze gives Risk Management Professionals the tools to find possible risks early, allowing them to take action before small issues become big problems. By protecting assets and processes, Qualityze helps create a strong risk management system that improves safety and reliability across the organization.

For Inventory Managers

Having the right spare parts when you need them is important for keeping maintenance running smoothly. Qualityze Maintenance Management helps Inventory Managers keep track of spare parts, get alerts when stock is low, and make sure all the needed parts are ready to avoid delays and prevent equipment downtime.

Experience the Qualityze Difference in managing maintenance processes with a free demo.

We understand that choosing the right Maintenance Management software is a crucial decision for your business. That’s why we encourage you to experience Qualityze in action through a free demo. Here are three compelling reasons to take advantage of this offer:

See AI-Powered Maintenance Management in Action

See how our intelligent, AI-powered Maintenance Management System can transform your maintenance processes. From creating flexible maintenance schedules to automating notifications and tracking nonconformance issues, Qualityze offers a user-friendly platform that helps you cut down on manual tasks, improve accuracy, and streamline asset maintenance—all in one place.

Discover What Your Ideal Maintenance Management System Should Look Like

Get a firsthand look at how Qualityze provides complete oversight of your maintenance activities. With real-time dashboards, proactive alerts, and insightful reports, you can make informed decisions to keep your equipment running smoothly, reduce downtime, and meet industry standards effortlessly.

Is It Worth the Hype? Find Out for Yourself!

See for yourself if Qualityze delivers on its promise to transform maintenance processes. Explore the features that make maintenance management efficient and compliant, while giving you the confidence that you’re choosing a solution that adds real value. Experience the capabilities that set Qualityze apart as a leader in the world of quality.

Ready to see Qualityze in action?

Request Demo

Frequently asked questions

Answers to commonly asked questions

If you have more questions feel free to reachout to us.

Contact UsGeneral

How does Qualityze Maintenance Management Software simplify asset maintenance?

Qualityze Maintenance Management Software simplifies asset maintenance by automating scheduling, tracking spare parts, and providing real-time visibility into equipment performance. It ensures operational excellence by helping organizations efficiently manage both scheduled and unscheduled maintenance while staying compliant with regulatory standards.

How does Qualityze Maintenance Management minimize equipment downtime?

Qualityze Maintenance Management enables businesses to implement proactive maintenance schedules, automate maintenance alerts, conduct timely inspections, and minimize equipment downtime. Regular and prompt maintenance activities help prevent unexpected failures and minimize production disruptions to ensure smoother operations.

What are the key features of Qualityze Maintenance Management Software?

Qualityze Maintenance Management Software offers several key features, including: Streamlined Maintenance Scheduling, Comprehensive Maintenance Execution for both scheduled and unscheduled tasks, Automated Maintenance Notifications, Enhanced Equipment Performance Visibility, and Controlled Maintenance Records and Data for compliance and audits.

Can Qualityze Maintenance Management integrate with existing business systems?

Yes, Qualityze Maintenance Management can seamlessly integrate with existing business systems like ERP and MES, allowing organizations to synchronize asset-related data across various platforms. It also integrates with Qualityze Nonconformance Management to handle maintenance-related issues efficiently.

How does Qualityze ensure compliance with industry standards?

Qualityze Maintenance Management adheres to various industry standards, including those set by the U.S. FDA, GMP, GLP, and GCP. It also supports compliance requirements for ISO and FDA 21 CFR Part 11 by providing features like electronic signatures, controlled data management, and maintenance certificates.

How can I manage spare parts effectively using Qualityze?

With Qualityze, you can easily create a comprehensive Spare Part Library with detailed information such as Spare Part Name, Quantity on Hand, Threshold Quantity, and Status. The system sends automated alerts when inventory falls below the threshold. It helps you avoid shortages and ensure that spare parts are always available when needed.

What are the benefits of defining Asset-Specific Maintenance Criteria in Qualityze?

Defining Asset-Specific Maintenance Criteria helps ensure that all assets are maintained according to their unique requirements. Qualityze allows users to establish standard measurements, tolerance levels, and units for each asset, which helps optimize maintenance activities, prolong equipment lifespan, and reduce maintenance costs.

How does Qualityze enhance equipment performance visibility?

Qualityze provides enhanced visibility into equipment performance through its robust reporting capabilities. It tracks maintenance activities, records key metrics, and identifies trends, enabling maintenance teams to make informed decisions to improve equipment reliability and optimize maintenance schedules.

Why is maintenance management important for operational excellence?

Maintenance management ensures the reliability of equipment, preventing unexpected breakdowns, and maintaining production efficiency. Qualityze Maintenance Management helps organizations reduce maintenance costs, extend asset lifespan, and ensure compliance with safety and quality standards, ultimately supporting operational excellence and a safer work environment.

Products

All Qualityze ProductsNonconformance ManagementCAPA ManagementDocument ManagementChange ManagementTraining ManagementAudit ManagementSupplier Quality ManagementComplaints ManagementCalibration ManagementMaintenance ManagementInspection ManagementPermit ManagementMaterial Compliance ManagementForms ManagementField Safety & Recall ManagementAdverse Events ManagementIncident ManagementRisk ManagementBatch Records Management8D Process

Industries

LifesciencesFood & BeveragesHealthcareManufacturingMedical DevicesPharmaceuticalsBiologicsBiotechnologyNutraceuticalsCannabisCompounded DrugsBlood & TissueAutomotiveAerospace & DefenseElectric VehiclePlastic and RubberElectronics and AppliancesChemical & AgrochemicalOil & GasEnergy & UtilitiesMetals & Mining

© 2025 Qualityze™ | All rights reserved. | Privacy Policy